Some words just get lost in translation. In France, they say remuage. Translated to English, the word is riddling. What is this riddling thing all about?

Although it has a funny name, riddling is actually a labor-intensive and intricate task in sparkling wine and Champagne production. The process itself was invented by a smart young woman who was annoyed with the cloudiness of the Champagnes of the early 1800s. These Champagnes were cloudy from the sediment left behind by the dead yeast from when the wine went through secondary fermentation. Not only did this sediment make the wine look bad, it also affected the taste.

Madame Barbe-Nicole Clicquot, head of Veuve Clicquot, noticed that when she shook the bottles, the sediment that was sticking to the sides of the bottle was loosened and eventually sunk to the bottom of the bottle when left upright. To get the sediment down to the neck, she decided to drill holes in her kitchen table and place the bottles upside down. That’s right. She drilled holes in her kitchen table. And the discovery of riddling was born.

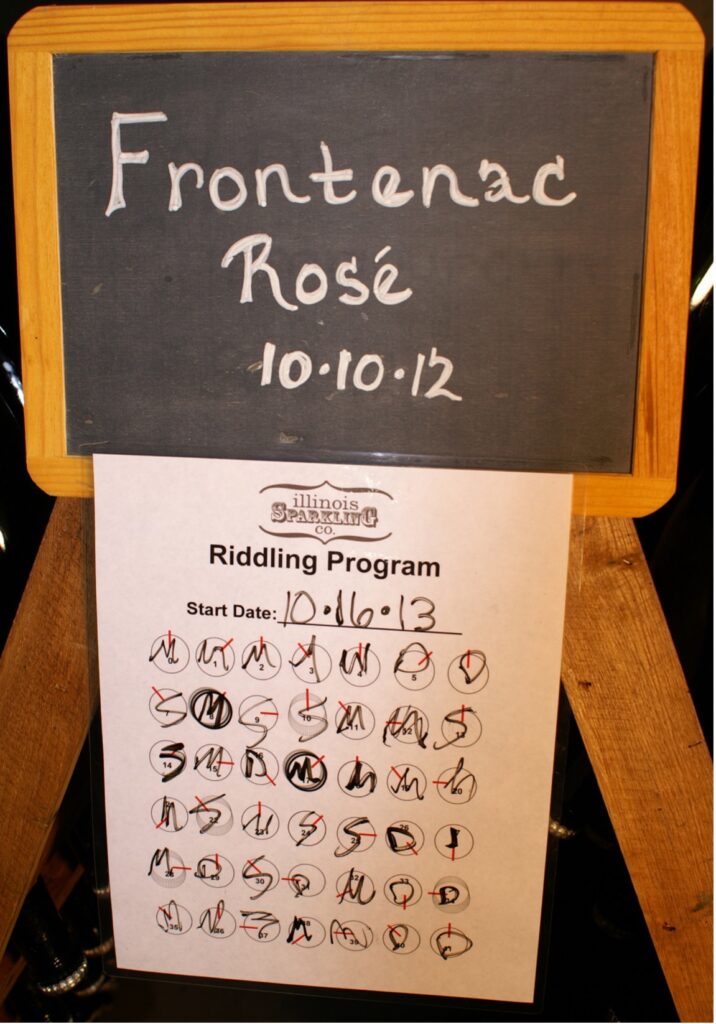

This process was modified slightly through the years and the kitchen table was replaced with specially built A-frame racks called pupitres; we call them riddling racks. The exact method of riddling varies by winery. When we first started producing ISC sparkling wines, we worked with a Champagne/sparkling wine expert from France to help us determine our manual riddling schedule. For wines that we manually riddle, each bottle is turned 41 times, by hand, during the riddling process.

When the riddling process is finished, the bottles are moved to the neck freezer and the disgorging process begins.

We now also have a gyro-palette machine located in our winery caves to help us with riddling, but we do continue to riddle some of our wines using this manual riddling process.